Assembly Test of the TAO telescope enclosure has been completed

TAO telescope enclosure

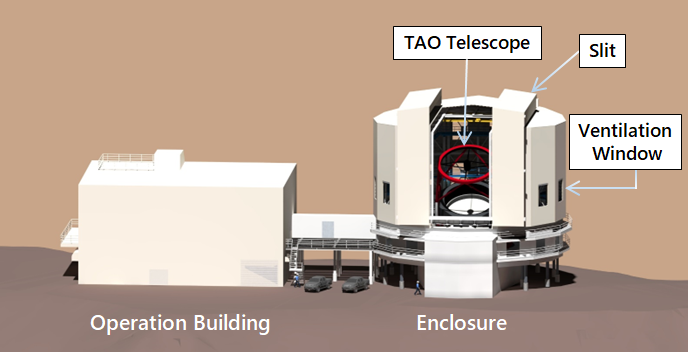

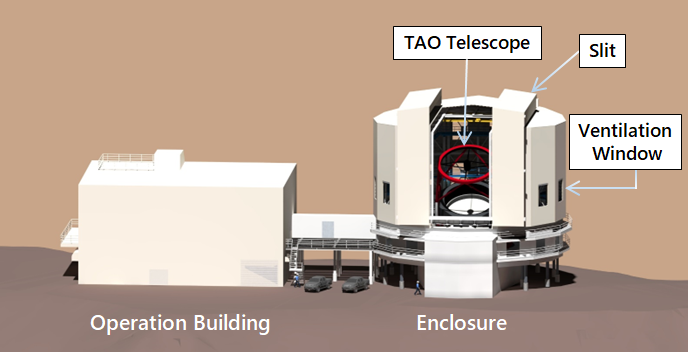

The TAO telescope is housed in a cylindrical building 25 meters in diameter and 24 meters high to protect precision instruments from the harsh natural environment at the summit of Co. Chajnantor, 5,640 meters above sea level. This building is called the enclosure (Fig. 1) . The TAO telescope is set 2.9 meters above the ground on an isolated foundation with a 10.4-meter diameter located at the center of the enclosure. It observes celestial objects through an open and closed door (slit) that can rotate horizontally. By making the enclosure a raised floor type, impacts of warm and turbulent air near the ground surface on the telescope are reduced. In addition, by opening the 19 ventilation windows on the enclosure walls and controlling airflow, the telescope achieves a high imaging performance.

The Operation building (27m x 17m x 15m high), connected to the enclosure by a bridge, will house a plant for cleaning and re-evaporating the telescope’s mirrors, as well as an observation room and laboratories which are necessary to carry out astronomical observations and maintain the instruments.

| |

▲Fig. 1 Conceptual drawing of the completed TAO telescope facility at the summit of Co. Chajnantor.

|

Temporary assembly test in Japan

The enclosure must be highly resistant to protect the telescope from high-velocity winds, low temperatures, and ultraviolet rays, and it must have high drive accuracy to track the movement of celestial objects. In addition, the enclosure's slits and ventilation windows must be closed to ensure protection of the telescope when weather conditions worsen. To achieve these performance requirements for the enclosure as a fortress of the TAO telescope and at the same time to ensure safe and efficient construction, we decided to fabricate, temporally assemble, perform a driving test, and adjust the upper part of the enclosure (horizontal rotating part) in Japan.

Fabrication and temporal assembly of the enclosure's upper part began in November 2016 in the rural landscape of Nose Town, located in the northern part of Osaka Prefecture. First, a steel plate was laid on a former agricultural land, on which 42 cart units that provide horizontal rotation power to the enclosure were fixed. The main structure of enclosure's upper part consists of an annular steel frame at the bottom and a primary steel frame rising from the bottom part, which are assembled into a cylindrical shape. These materials were assembled with a limited number of heavy machines, scaffolding, and workers to simulate work on the summit of Co. Chajnantor (Fig. 2).

| |

▲Fig. 2 Main structure of the enclosure that has started to be assembled (Nose Town, Osaka)

|

Next to the main structure, the base materials (furring strips and purlins) for attaching insulation plate materials to the walls and roof were assembled. At the same time, a large slit opening/closing system was installed (Fig. 3). Nineteen roll-up shutter-type ventilation window units and an inspection walkway were installed on the walls (Fig. 4). An overhead crane was installed near the ceiling for maintenance of the telescope and instruments (Fig. 5). Wind breaker units were installed at the opening part of the slit to control the wind flow into the enclosure. Multiple perforated boards are folded in a bellows fold and spread upward as needed (Fig. 6). Insulation plates for the walls and ceilings were cut to size from the actual temporarily assembled enclosure so that construction could proceed efficiently on site.

| |

▲Fig. 3 From the front of the enclosure. With the slit open.

|

| |

▲Fig. 4 From the back of the enclosure. The ventilation window units (8 white rectangles) installed on the wall are visible.

|

| |

▲Fig. 5 View of the countryside from near the ceiling. The equipment wrapped in a blue sheet, as seen in the center right, is an overhead crane.

|

| |

▲Fig. 6 With the slit closed. The white board with holes is the windbreaker unit.

|

Operation tests of the moving parts were conducted by connecting the control unit that can manage all the moving parts installed in the enclosure. To ensure the smooth operation of the enclosure, which is a huge robotic structure, patient adjustment and modification of each part were necessary. This task is challenging to accomplish at the summit of Co. Chajnantor, which is 5,640 meters above sea level. After two years of work, the steel cage of the enclosure is now able to agilely and smoothly cut through the landscape of Nose Town while freely moving its various parts.

In January 2019, the enclosure began to be disassembled for shipping by sea to Chile in South America (Fig. 7). The next time we will see the enclosure in its massive form will be on the other side of the globe at the summit of Co. Chajnantor. The enclosure was disassembled in just two months. After that, the movable units were disassembled and serviced for reassembly on-site, and the steel frame material was rusted away from storage and repainted (Fig. 8).

| |

▲Fig. 7 The disassembled enclosure structure being loaded onto a trailer.

|

| |

▲Fig. 8 Repainted enclosure furring material (Kishiwada City, Osaka)

|

The repainted enclosure materials will be export-packed strictly to withstand long-term transportation and storage and then loaded onto several container vessels for departure from the Port of Kobe to the ports of Antofagasta or Angamos in Chile. Preparations will now be made to ensure that the enclosures are safely transported to Chile and that construction and operation can begin smoothly.

| |

▲Fig. 9 Enclosure materials after export packing

|

|