|

A graduate student got a master's degree related to the instrumentation for the TAO telescope!

Kono, who belongs to the Department of Astronomy, Graduate School of Science, the University of Tokyo, and has worked as a main member of the development team of the instrument "Simultaneous-color

Wide-field Infrared Multi-object Spectrograph, SWIMS" for TAO 6.5m telescope, received a master's degree. We introduce the results of his two years of hard work and research.

Development of SWIMS-IFU, an integral field unit for a near-infrared multi-object spectrograph

Department of Astronomy, Graduate School of Science, the University of Tokyo, Master’s Course

Yukihiro Kono

|

Near-infrared multi-object spectrograph, SWIMS, developed in our lab, plans to have integral field spectroscopy (IFS) capability in addition to imaging and slit-spectroscopy capability.

Since slit spectroscopy obtains wavelength information in one spatial dimension with a single observation, for spatially extended objects such as galaxies, we need to repeatedly observe them while shifting the slit little by little to obtain wavelength information for the entire object. This is very time-consuming and observation efficiency is poor. One solution to this problem is IFS. Using a special optical system, IFS can disperse the light from celestial bodies spread over two spatial dimensions, enabling efficient observations.

Our integral field unit, SWIMS-IFU, adopts the 'image-slicer method'. In this method, a mirror array is used to cut the celestial image into multiple strips and rearrange them in a row to form a pseudo-slit image, which is dispersed to acquire wavelength information from an object spread over two spatial dimensions. To realize this method, we need optical elements with very complicated structures. We conducted research to demonstrate the feasibility of fabricating these optical elements.

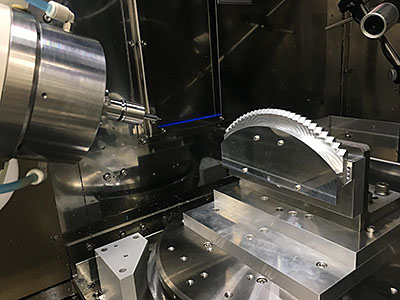

In my research, we tried to fabricate an optical element called 'slit mirror array', which is one of the mirror arrays of SWIMS-IFU and consists of 26 spherical mirrors arranged in an arch shape. We used an ultra-precision cutting technique for it. In our lab, it had already been demonstrated that we could produce a slice mirror array consisting of 26 plane mirrors with the ultra-precision cutting technique. However, we didn't know whether we could produce a slit mirror array consisting of spherical mirrors. To address this, we focused on the 'ball end mill', a tool with a circular cutting edge that enables flexible processing, and conducted a fabrication test.

As a result, we could obtain mirrors which meet our requirements (a shape error of P-V < 100nm, surface roughness of RMS < 10nm), and it was also suggested that the relative position between mirrors can be processed with high accuracy. We also demonstrated that special aluminum alloys RSA6061 could be used as mirror base material. This allows us to fabricate SWIMS-IFU with a single type of metal, so it is expected that distortion caused by low temperatures can be suppressed.

▲Processed slit mirror array (right) and ultra-precision cutting machine

▲The author working as a SWIMS team member (left)

|

|