|

|

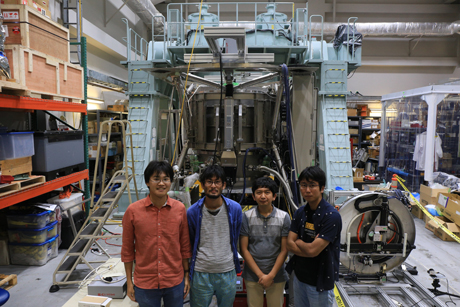

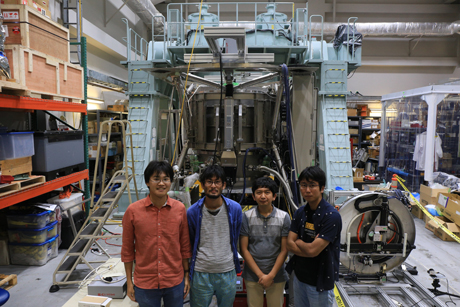

MIMIZUKU and its developing members. MIMIZUKU was transported to Hawaii after the completion of its development works in Japan.

|

The TAO 6.5-m telescope's 1st-generation mid-infrared instrument, MIMIZUKU, has completed its development in Japan. However, there are still many tests to go through before starting its scientific operation: confirming its secure attachment to the telescope, confirming its detectivity of astronomical objects, and so on.

And if unexpected problems occurred during these tests, further development has to be done to solve the problems.

Unfortunately, the TAO observation site, which is located at 5,640m above sea level, is too severe for human being to conduct these tests and development.

Therefore, we proposed to conduct engineering observations for these tests on the Subaru telescope in the National Astronomical Observatory Japan (NAOJ) Hawaii Observatory, because this observatory is located at a good place for mid-infrared observations and has nice development facilities. Our proposal has been approved after two reviews by the observatory. For these engineering observations, MIMIZUKU was transported to Hawaii.

|

|

|

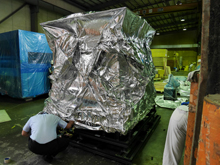

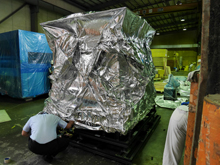

MIMIZUKU body, vacuum-packed at the shipping company's factory(left), and packed in the steel case (right).

|

|

|

|

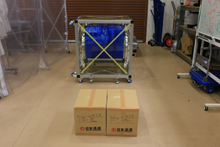

Optics before packing (left) and after packing (right).

It is placed on a special black palette which suppresses vibration during the transportation.

|

MIMIZUKU was transported with two ways to reduce cost and damages. One is by air, and the other is by sea.

Temperature changes and vibrations could cause damages during the transport. In air transport, such damages would not be so serious, but transport fees tend to become expensive. On the other hand, shipping costs relatively low, but since temperature changes and vibrations could be extensive, it is not suitable to send fragile pieces.

Therefore, the optical system that is fragile to temperature changes and vibrations was transported by Air, and other parts were transported by ship. Marine and air transportation departed from IoA on August 25 and September 20, respectively, and both arrived at the Hilo-Office in NAOJ Hawaii Observatory on October 11. Uchiyama, Mori, Yamaguchi, post-graduate students from Miyata Laboratory, and Kamizuka, a postdoctoral fellow, visited Hawaii to receive the baggage and conducted experiments to confirm whether they had arrived without any damages or not.

|

|

|

Wooden boxes were brought in one after another (left) and steel case storing MIMIZUKU (right).

|

Unpacking was the first work in Hawaii. The transported items were packed in wooden boxes and a steel case, and have to be unpacked one by one. Some mold was found inside the wooden boxes, and rust was found on the steel case. They indicate high humidity during the transportation. However, the items inside the box remained unharmed because of the vacuum packing.

|

|

|

Mold found in the wooden box (left) and rust generated on the steel case (right).

|

|

|

|

Vacuum-packed items. Silver packing has airtightness, preventing damages from outside humidity and temperature change by making the inside a vacuum. |

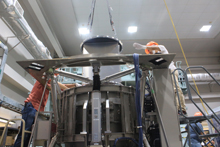

No damage was found in appearance, but for checking invisible damage in the equipment, we performed total functional tests: cooling the optical system, driving the detector, and acquiring images of the outside light sources. The performance tests conducted successively: the equipment was assembled again, and the chamber was vacuumed followed by the cooling process. The cooling process has been completed in October 30. The detector was successfully cooled to 3 K which is lower than the experiments in Mitaka. This is because the cooling power of the cryocoolers was improved due to the high frequency of the AC power supply in Hawaii. From this experiment, it was confirmed that there was no damage in cooling capability.

|

|

|

Installation of optics to the vacuum chamber (left) and infrared detector (right), that were dismounted for transport.

|

|

|

|

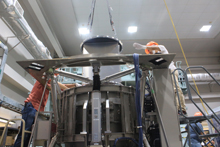

MIMIZUKU during pre-cooling process. Liquid nitrogen, transferred from the tank (center) to MIMIZUKU, realizes fast cooling down to 100 K.

|

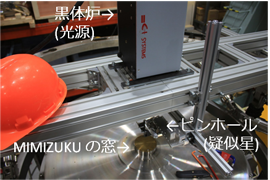

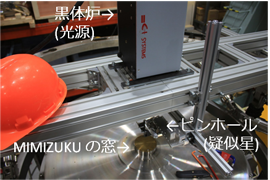

Since cooling completed without any problem, the detector got ready for use, and we moved on to imaging tests using the detector. Small holes called pinhole apertures (15 and 50 microns in diameter) were placed on MIMIZUKU, and they were illuminated by an infrared light source called blackbody furnace to show pseud stellar images to MIMIZUKU. The performance of the camera was evaluated in this imaging test. As a result, we confirmed that MIMIZUKU can take sharp images with good sensitivity as expected. By this result, it was also confirmed that no damage had occurred in optical system through transportation.

|

|

|

Set-up of the infrared imaging test (left) and obtained infrared image of the pinhole aperture irradiated by the blackbody furnace (right). |

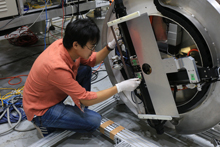

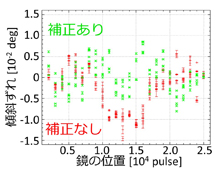

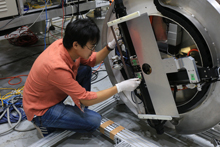

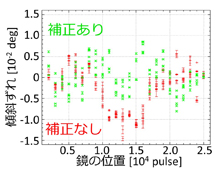

Additionally, a special device called field stacker is installed in MIMIZUKU. This is a key device for realizing "highly precise observation" that MIMIZUKU aims for. Plural mirrors are equipped on this device, and precise control of the mirror positions enables highly precise observations. The position control tests were also conducted in Hawaii. Since unwanted pitch motion had been confirmed in linear motion of the mirrors, a program which compensates it by tilting mirrors inversely was developed and tested. Improvements in the motion was confirmed through the tests as shown in the figure.

|

|

|

Post-graduate student, Mr. Uchiyama, conducting the adjustment of field stacker (left). Right panel is the results of the measurements that had been obtained. Without the compensation (red), a pitch displacement occurred near the center, but with the compensation (green) they were successfully corrected. |

With completion of the tests mentioned above, the members came back to Japan. From now on, we will develop software, and visit Hawaii again from April 2018 for preparations for the engineering observations. The observation will be conducted early in July, 2018. In the observations, along with mid-infrared imaging and spectroscopy tests, we will demonstrate the effects of the field stacker device on improving observation precision. We will go ahead with the preparations in order to make a success of the engineering observations.

|

|

Development members who finished a series of test experiments. At Hilo-office laboratory at Hawaii Observatory.

|